Polat continuous olive oil production systems used in olive oil production consist of set of machinery which are connected to each other operate collectively. In addition to turnkey continue systems designed and produced by Polat Makina, it offers solutions as single part machinery options which you will need in your processes. All equipment needed in the system are produced by Polat Makina in compliance with food regulations and CE standards.

- In continuous systems of Polat Makina, olive is taken from the branch, separated, washed and broken. This process is finalized with kneading the olive paste and obtaining olive oil. Olive oil is produced with zero-touch from the first stage to the last stage.

-

- Cleaning:Cleaning phase of the olives is of vital importance for the oil quality and equipment safety. Olives are separated from bugs, leaves, branches, stones, soil, etc.

-

- Breaking:Olives cleaned are carried to the breaker with a spiral. Olives are broken swiftly with the automation control parameters suitable for continue system and transformed into paste for the next stage.

-

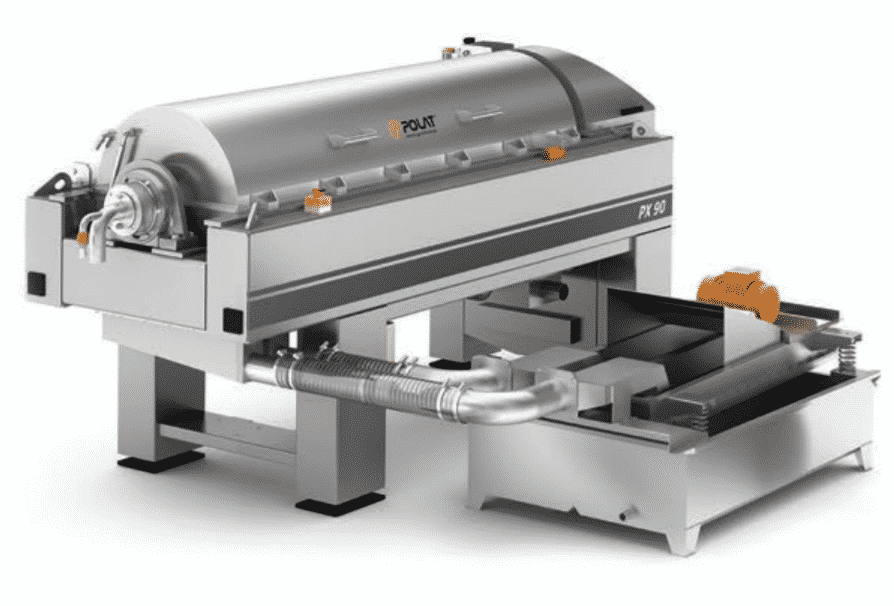

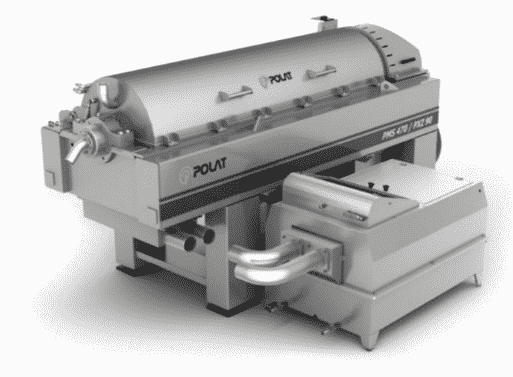

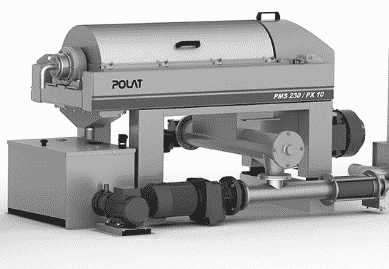

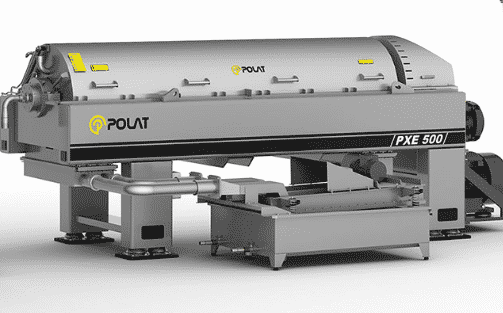

- Kneading (Malaxation):The product broken and transformed into paste enters into malaxation system. In the malaxation system, the paste is kneaded for maximum 90 minutes in 20-25°C and prepared for the next stage. The aim of this process is to separate the oil from its cells and gather and transformed into free form.

-

- Separation of Oil:The product is transferred to the oil squeezing stage which is the following part of the malaxator after the consistence of the product is obtained. In this stage, water (black water), solid (olive pomace) and oil within the paste are separated through decanter centrifuge method. Oil is obtained by 2 or 3-phase product separation in compliance with your facility in this stage.

- Cleaning the Oil:Oil obtained after squeezing is put into the separator as the final stage and separated from the foreign materials and then sent to stock tanks