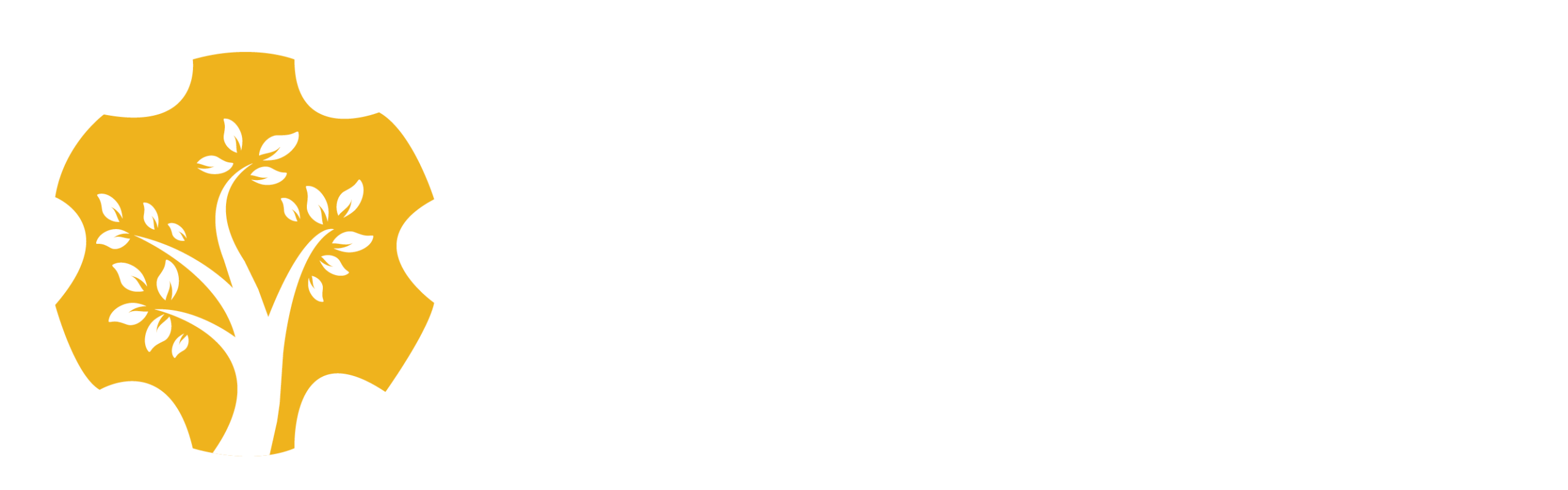

Sieving Machine Types

4 meters with 15 Threads

Technical Specifications

- Adjustable division distance

- Possibility of increasing and reducing the number of divisions

- 4 m sieving distance

- 10 mm special knitted thread

- 15 threads

- Thread stretching apparatus

- Electronic speed control

- 10 divisions

- Feed band

- Transfer band which spreads olives

- Leave and dust removing fan

- AISI 304 body

- PVC bands in compliance with FDA

- 1250-1500 kg/h max. capacity

- 220 V

- Ip 65 plastic electrical board

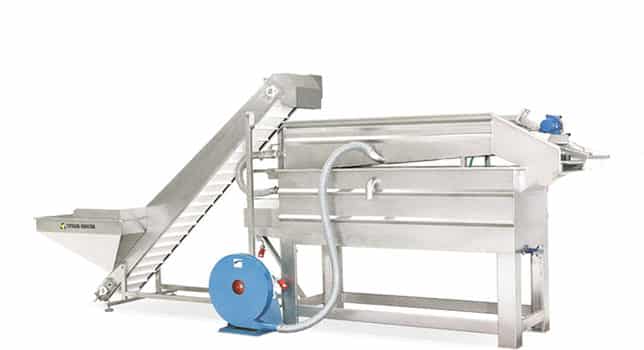

4 m with 25 Threads

Technical Specifications

- Adjustable division distance

- Possibility of increasing and reducing the number of divisions

- 4 m sieving distance

- 10 mm special knitted thread

- 25 threads

- Thread stretching apparatus

- Electronic speed control

- 10 divisions

- Feed band

- Transfer band which spreads olives

- Leave and dust removing fan

- AISI 304 stainless body and equipment

- PVC bands in compliance with FDA

- 3500 4000 kg/h max. capacity

- 220 V

- Ip 65 plastic electrical board

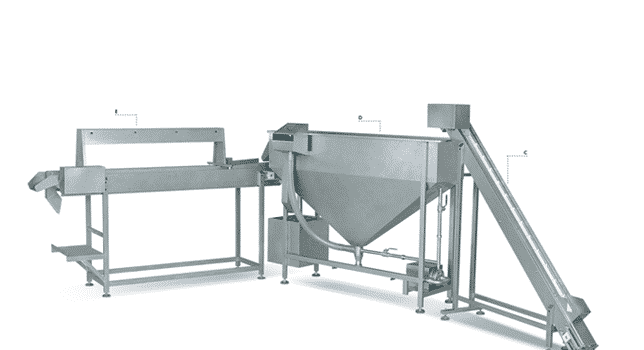

6 m with 20 Threads

Technical Specifications

- Adjustable division distance

- Possibility of increasing and reducing the number of divisions

- 6 m sieving distance

- 10 mm special knitted thread

- 20 threads

- Thread stretching apparatus

- Electronic speed control

- Feed band with speed control for continuous good supply

- 10 divisions

- Transfer band which spreads olives

- Leave and dust removing fan

- AISI 304 stainless body and equipment

- PVC bands in compliance with FDA

- 2500 3000 kg/h max. capacity

- 220 V

- Ip 65 plastic electrical board

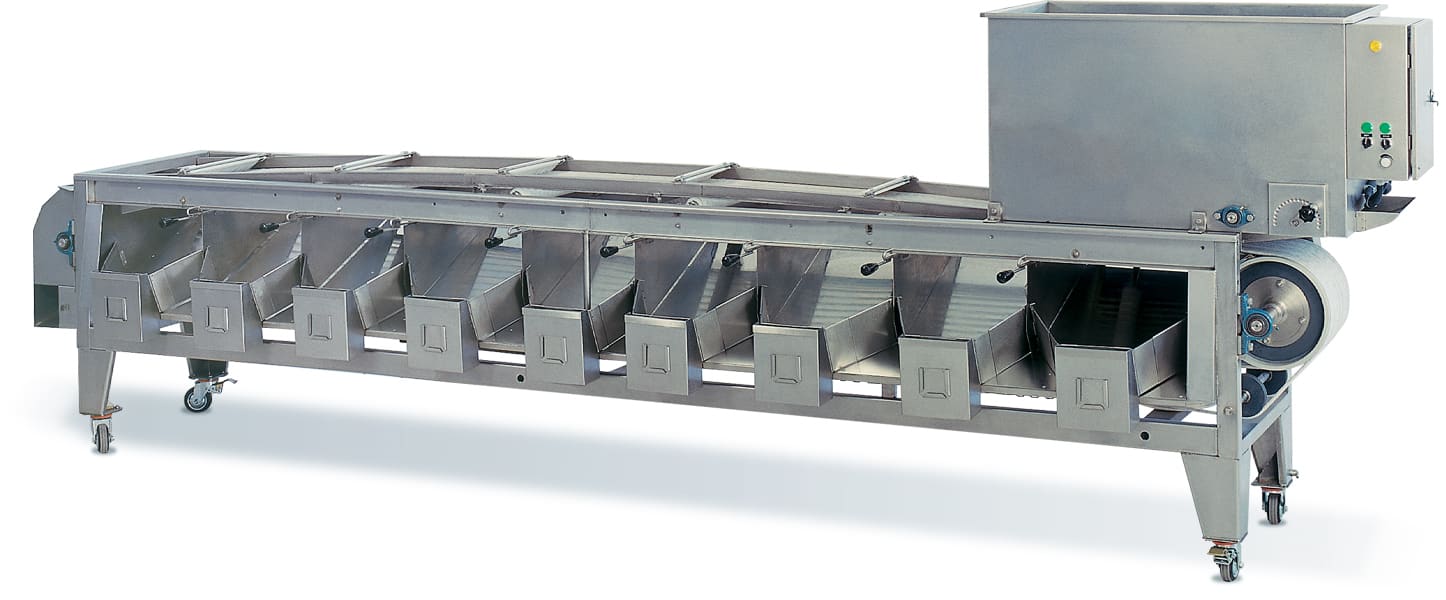

10 m with 20 Threads

Technical Specifications

- Adjustable division distance

- Possibility of increasing and reducing the number of divisions

- 10 m sieving distance

- 10 mm special knitted thread

- 20 threads

- Thread stretching apparatus

- Electronic speed control

- Feed band with speed control for continuous good supply

- 16 divisions

- Transfer band which spreads olives

- Leave and dust removing fan

- AISI 304 body

- PVC bands in compliance with FDA

- 2500 3000 kg/h max. capacity

- Ip 65 plastic electrical board

10 m with 40 Threads

Technical Specifications

- Adjustable division distance

- Possibility of increasing and reducing the number of divisions

- 10 m sieving distance

- 10 mm special knitted thread

- 40 threads

- Thread stretching apparatus

- Electronic speed control

- Modular feed band with speed control for continuous good supply

- 16 divisions

- Modular transfer band which spreads olives

- Leave and dust removing fan

- AISI 304 body

- 9000-10000 kg/h max. capacity

- Ip 65 plastic electrical board